Laboratory of Synthesis of New Superhard Materials

Laboratory Head, Dr. A. PozdnyakovResearch areas

- Development and improvement of high-pressure equipment.

- Improvement of HPHT methods of synthesis of superhard and ultrahard materials with specified data and study of their properties.

- Development of methods and technologies for production of novel nanostructured functional and structural materials with improved properties.

|

|

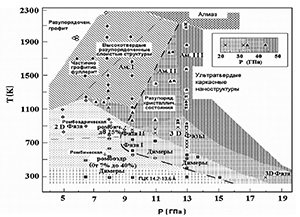

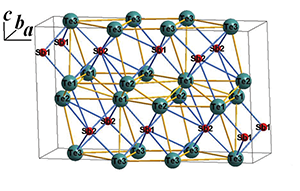

| P, T -fields for the synthesis of fullerite C60 | The structure of the Sb2Te3 metastable phase. Te1-Te2 layers are pulled together in the middle of the unit cell |

Results

Employees of the laboratory together with other subdivisions of FSBI TISNCM carried out a pioneer work on the preparation

and study of the structure and properties of superhard and ultrahard phases of C60 and C70.

New metastable phases of antimony telluride and bismuth, the most important thermoelectrics near room temperature, were synthesized by rapid cooling after the high pressure (4 GPa) and temperature (600-700° C). By using X-Ray powder diffraction the crystal structure of obtained phases was defined, in which the layered structure is preserved, but alternation of layers is changed. Under the influence of high pressure atomic layers approach each other and metallic bond is formed between the Te- Te layers. New phases have superconducting properties.

Laboratory has obtained:

- a superhard composite (RF invention patent number 2491987 priority 17.11.2011, published on 10.09.2013) based on boron and carbon, which may be used as pressure vessels, the cutting tools with high wear resistance and tool elements for drilling.

- carbon-nitrogen material (RF invention patent number 2485947, priority of 03.11.2011, published on 20.06.2013), which can be used in production of damping elements, dampers, friction pairs and wear-resisting part of micromachines.

Invention patents applied

Method for obtaining superhard composite material (Number 2012152827/05 from 07.12.2012) based on a fullerene which can be used to make tools for mining, stone processing and metalworking industry.

Method of producing ultra-hard material (Number 2013143992 from 01.10.2013) based on boron and carbon, which may be used in production of cutting tools,

drilling tools, and for other applications where high-wearing feature is required.

Research of physical and mechanical properties

- bulk carbon materials based on the fullerenes with high mechanical properties;

- materials based on the nanotubes synthesized under different conditions;

- metal-carbon composites obtained by a thermobaric treatment;

- superhard material powders with different characteristics.

The laboratory staff conducts the experiments to obtain the test samples of the superhard materials powders with the desired morphological characteristics, magnetic and nonmagnetic properties, and higher heat resistance.

The superhard materials powders are checked for compliance with the applicable domestic and international standards through the following methods:

- determining the powder grain composition;

- identification of the morphological characteristics of the powders;

- determination of the powder static strength;

- determination of the powder dynamic strength;

- verification of powder thermal stability after annealing in an inert atmosphere;

- determination of non-combustible impurities content in the powders;

- determination of moisture content in the powders;

- abrasive ability identification for the micropowders.

The physical and mechanical properties of the bulk samples are studied in the Laboratory, including the following research:

- measurement of density;

- measurement of microhardness;

- measurement of fracture toughness;

- sample preparation;

- metallographic studies;

- development of the unique methods for the surface preparation of the samples in a wide range of hardness values (0,4-50 GPa) for materialographic research;

- development of the parameter measuring techniques for the surface and mechanical properties of the materials for the scanning probe microscopes and nanohardness testers.

DEVICES AND EQUIPMENT

- KERN-770-60 Electronic laboratory scales (Germany, accuracy class the GOST 24104-88-1 standard) with a Sartorius YDK 01 LP density measuring attachment;

- Olympus BX51Optical Microscope, the total increase maximum 3000x, available methods: dark field, bright field, differential interference contrast (DIC). It is intended for research in both transmitted and reflected light;

- A furnace with a programmable controller for the heat treatment of materials in an inert atmosphere (argon), operating temperature up to 1150 ºC;

- Equipment for the powdered materials classification (separators and sets of sieves, complying with the relevant domestic and foreign standards, an electromagnetic roll separator, a vibratory separator);

- The equipment for determining the properties of the grinding and micro-powders of the superhard materials (a DDA-33 Friability Tester);

- A ПМТ-3М microhardness tester;

- A DuraScan Micro-Hardness Tester, EMCO-TEST, Austria;

- A Lectro Pol-5Automatic device for electrolytic polishing and etching, Struers, Denmark;

- Tegra Pol-11grinding and polishing equipment, Stuers, Denmark.

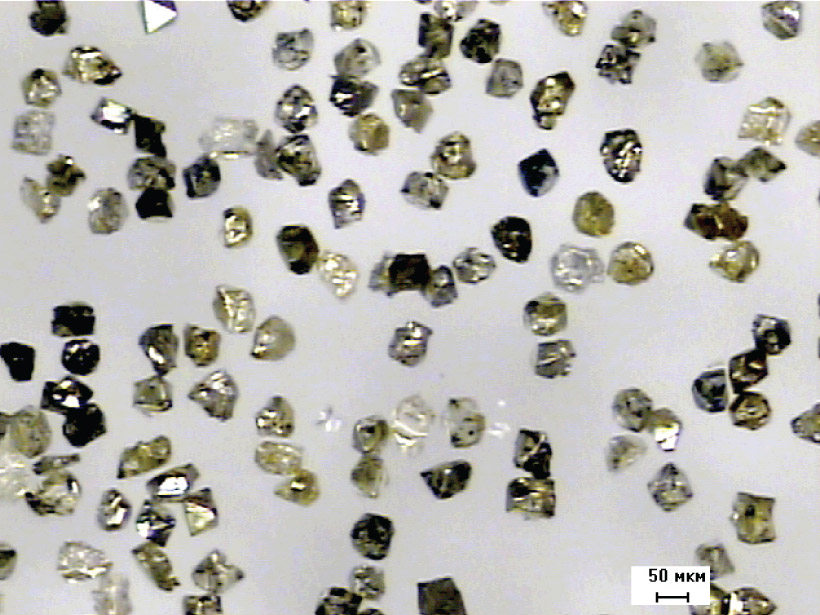

АСМ synthetic diamond micropowder with a 63/53 grain size |

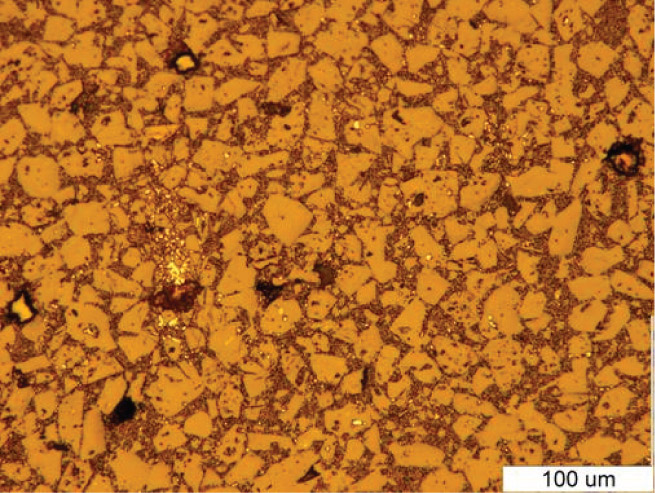

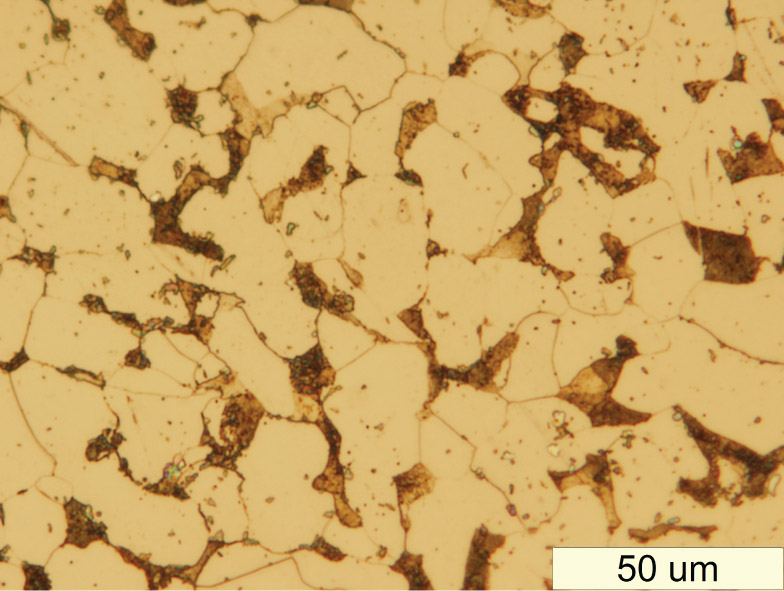

Microstructure of the cubic boron nitride |

Microstructure of the copper nanotubes |

Microstructure of steel with nanodiamonds |