Goals and objectives of the Section: |

|

|

Integrated studies of the physical and mechanical properties of different types of materials, carbon nanostructures and composites on their basis, including thin films and coatings, diamonds and diamond powders. Section Head:Dr. A. Useinov Staff:

|

||

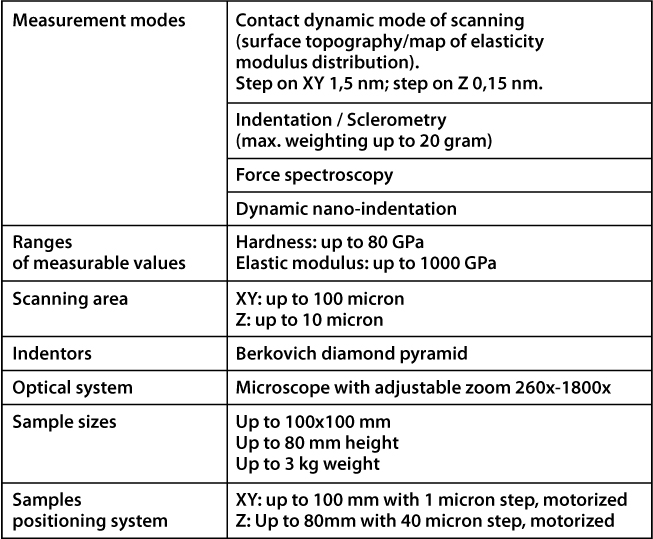

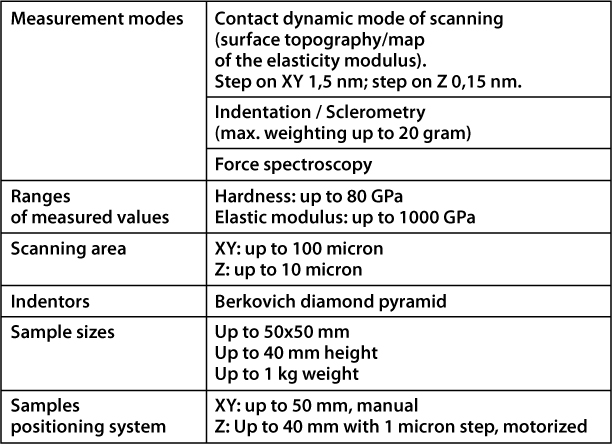

Types and ranges of measurements: |

|

Scanning Probe Microscopy |

|

|

"Integra Prima" (NT-MDT, Russia) Scanning Probe NanoLaboratory Integrated studies of different objects with high spatial resolution. Available SPM measuring methods:

|

| |

|

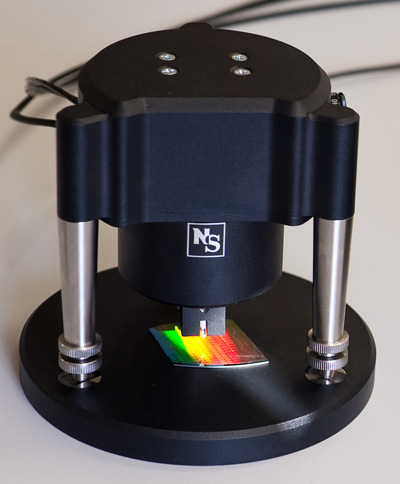

Scanning nano-hardness "NanoScan" family Integrated studies of relief and surface structures and mechanical properties measurements (including hardness and elasticity modulus) of bulk materials and thin films at submicron and nanometer length scale. Mapping of the surface topography by raster scanning with 1,5 nm step in scanning area up to 100 microns. |

|

| |

|

|

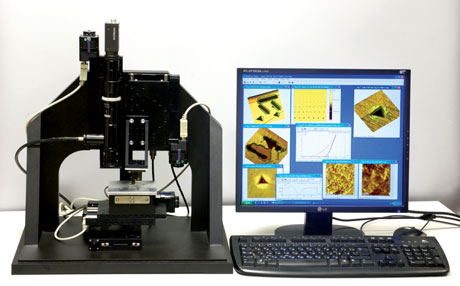

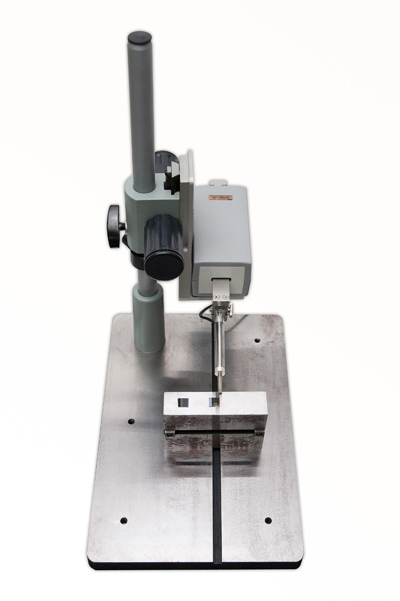

Scanning nano-hardness tester "NanoScan-3D"

|

| |

|

|

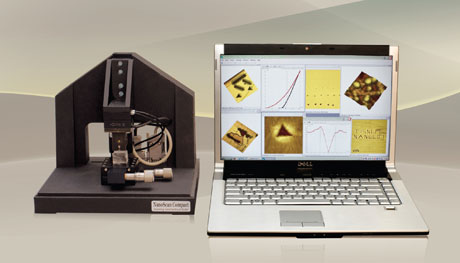

Scanning nano-hardness "NanoScan-Compact"

|

Measurements of Density,

Preparation of the samples for metallographic studies is provided by polishing equipment made by "Struers" company. |

|

|

Density measurements: "KERN-770-60" Laboratory and Analytical Balance (Germany) (accuracy class according to GOST 24104-88 – 1, Certificate DE.C.28.001.A № 9542), with "Sartorius YDK 01 LP" add-on density measurement device Weighing capacity range: |

| |

|

|

Optical microscopy: BX51 microscope (manufacturer "Olympus" company) Provides research in transmitted and reflected light. Max. range of total magnification 3000x. Available study methods: bright field, dark field, Nomarski differential interference contrast, polarization. |

| |

|

|

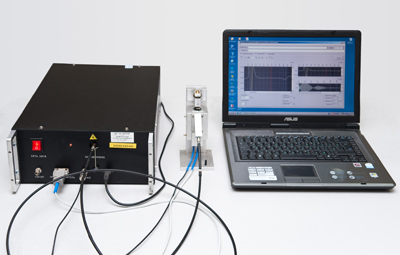

Measurements of sound velocities and elastic modulus: UDL-2M Laser and Ultrasonic Flaw Detector (manufacturer "OK Vinfin") Provides precision measurements of phase velocity of longitudinal ultrasonic waves in samples of various constructional materials (metals, alloys, ceramics, plastics, composites) with one-sided access to the sample. Frequency range of opto-acoustic transducer: 0,1 - 15 MHz, thickness of the object of control: 0,2 - 100 mm, range of the measured velocity of ultrasound: (0,1 - 99) × 103 m/s, maximum relative accuracy: 3%. The system has elastic modulus of material measurement mode for small samples. |

| |

|

|

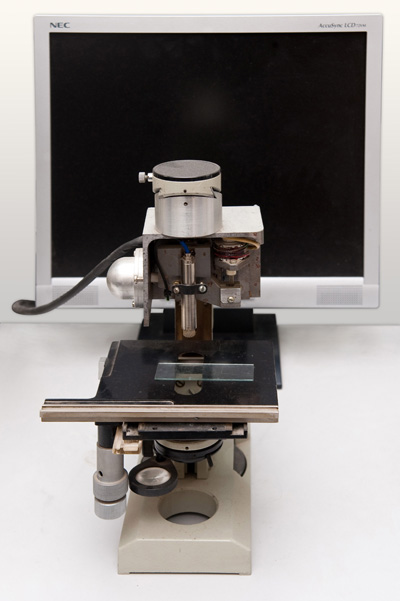

High-frequency Broadband Impulse Acoustic Microscope (manufactured by AMC of the Institute of Bioorganic Chemistry RAS, Russia) Broadband acoustic scanning microscope provides studies of the inner microstructure of the solids by acoustic A-scanning method, B-scanning method and method of V(Z)-curves. Works in the reflection mode at frequencies of 25 MHz and 100 MHz in a pulse mode (with duration of 30 ns) and continuous modes. Mechanical scanning unit provides precise scanning with acoustic lens along the X direction (parallel to the surface), and Z (perpendicular to the surface). On samples with plane-parallel faces, velocity of ultrasonic longitudinal and shear waves can be measured with an accuracy of ~ 1%. |

| |

|

|

Measurements of hardness and roughness: "Profi-130" Profiler-Nanoprofilometer (manufacturer MIET) With sensitivity of 0,0002 microns, the System measures 22 roughness parameters and 4 parameters of corrugations of external and internal (grooves, holes) surfaces, which cross-sections in a measurement plane can be both straight lines and bend round lines (balls, rollers, etc.) with measurement of the radius. |

| |

|

|

PMT-3M1Hardness Tester

|